Production Chart

Mixing of raw materials in form of resins

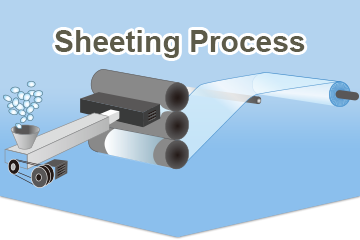

Sheeting - Transforming resins into sheets

Output in roll form for thermoforming process

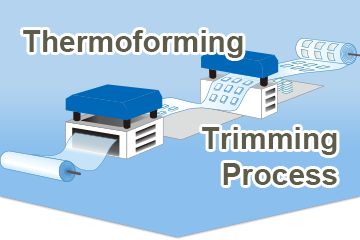

Thermoforming and trimming -Transforming sheets into food trays (finished products)

Quality inspections throughout the entire process by line workers and QC team

Packing into bags and cartons end of production line

Storage and preparation for distributions by warehouse and logistic staffs

Transportation to customers with worldwide distribution networks

Final delivery to end-users all over the world

HIRO FOOD uses certified raw plastic material to increace food safety.

We set strict quality standards throughout the entire supply chain process.